Create Your First Project

Start adding your projects to your portfolio. Click on "Manage Projects" to get started

Rube Goldberg Machine

Roles

Track & Field Event Lead; Elevator Construction Lead

Location

Duke University, Durham, NC

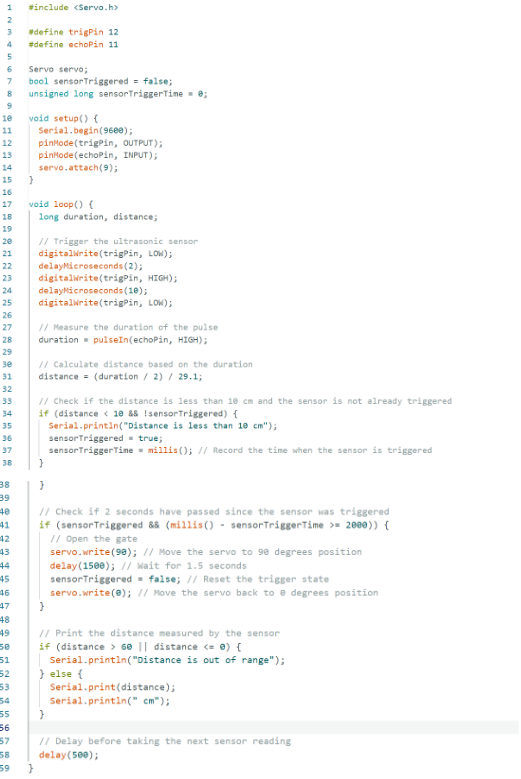

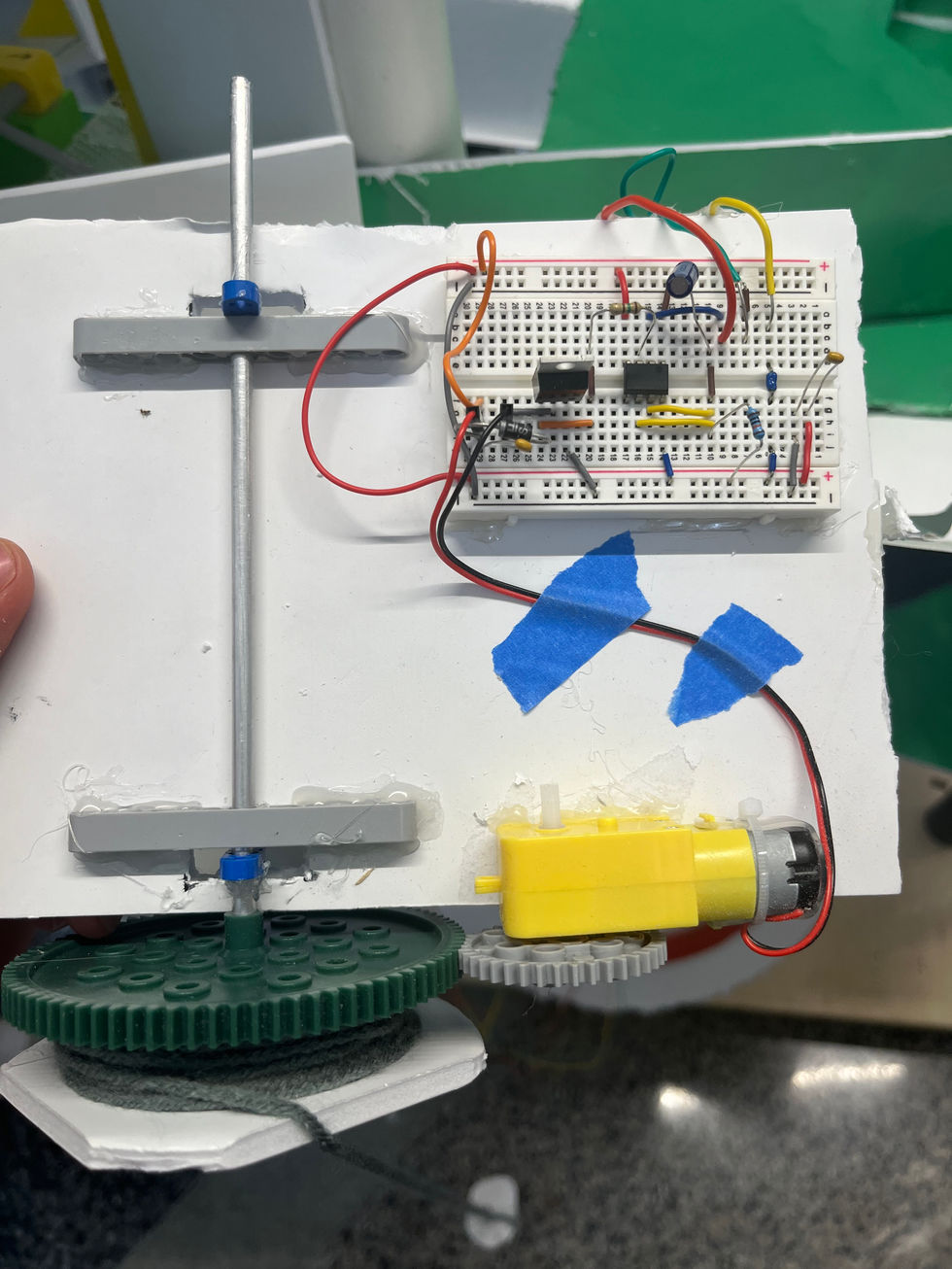

Team of undergraduate Mechanical Engineering students divide into four subteams to assemble an intricate Rube Goldberg machine. Our team chose to divide each subteam's contribution to the machine into Olympic events, which all must fit together and allow for smooth track transitions. Each subteam responsible for the creation of two Olympic events, one summer and one winter, each with integrated electronic components that automatically activate upon the ball's entry. Our subteam's segments consisted of a track event and ski-jump event. The track, built by myself, includes a switch that, after a short delay activates an elevator. The elevator consists of a pulley system controlled by gears spun by a motor on a 555 timer circuit. The pulley utilizes the mechanical advantage to pull the ball through a chute that leads to the next Olympic event (situated at a higher level to gain potential energy and keep the ball rolling "naturally"). An ultrasonic sensor was used to detect when the ball passed through the ski-jump event, opening gates to the launch track. The Pratt School of Engineering contest between different teams (consisting of different subteams) within the Mechanical Engineering Dept. required two full non-interfered runs. Our team succeeded in the first run, and satisfied the second successful run a few trials later.